- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

How to select stepper motor and stepper motor driver?

How to select stepper motor and stepper motor driver

Stepper motor is an open-loop control element that converts electrical pulse signal into angular or linear displacement. There are three main types of structure: reactive, permanent magnetic, and mixed. A stepper motor driver is an actuator that converts electrical impulses into angular displacements. When the stepper driver receives an impulse, it drives the stepper motor to rotate at a fixed Angle (called the "step Angle ") in the set direction. The angular displacement can be controlled by controlling the number of pulses so as to achieve accurate positioning. At the same time, the speed and acceleration of the motor can be controlled by controlling the pulse frequency, so as to achieve the purpose of speed regulation and positioning.

Torque is one of the main parameters of stepping motor. When the load is large, the high-torque motor should be used. When the torque index is large, the motor shape is also large.

Judge the motor running speed: when the speed is required to be high, the motor with large phase current and small inductance should be selected to increase the power input. And when selecting the driver, use a high supply voltage.

Select the installation specifications of the motor, such as 57, 86, 110, etc., mainly related to torque requirements. The larger the number of specifications, the greater the torque.

And in the selection of stepper motor driver, first look at the volume requirements, and now the market on the volume requirements of the driver is getting higher and higher, so small stepper motor driver is generally the first choice. Secondly, determine the positioning accuracy and vibration requirements: determine how much subdivision is required. The higher the subdivision, the higher the precision. And vibration, stepping motor will have a resonance range, when the speed is just within this range, the vibration will be very big, you can use high subdivision to narrow the resonance range.

When the stepping motor moves, the torque will decrease with the increase of the speed. Therefore, when choosing the stepping motor, the relationship between torque and speed should be balanced.

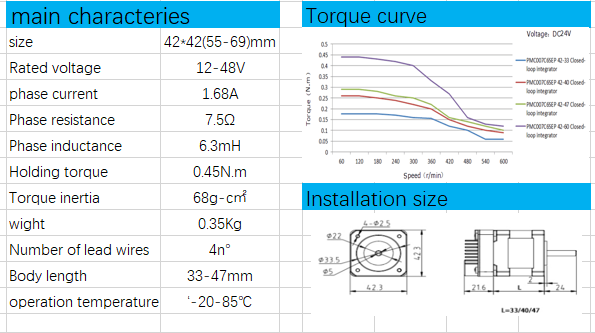

When selecting a stepper motor and a small drive controller, the main parameters to look at are torque, speed, subdivision, voltage, and current. As shown in the figure below, many manufacturers will give these parameters, and customers can basically determine the type selection according to their own needs.