- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

How to Choose an Appropriate Stepper Motor Control System

Motor type selection:

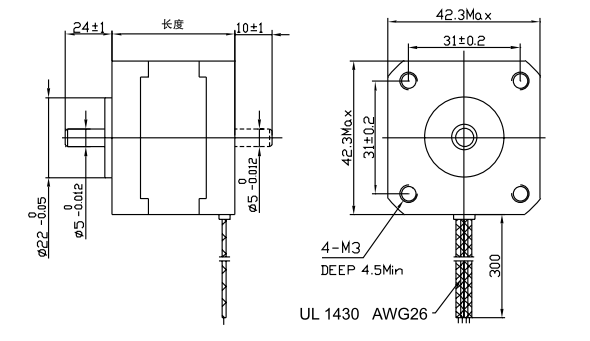

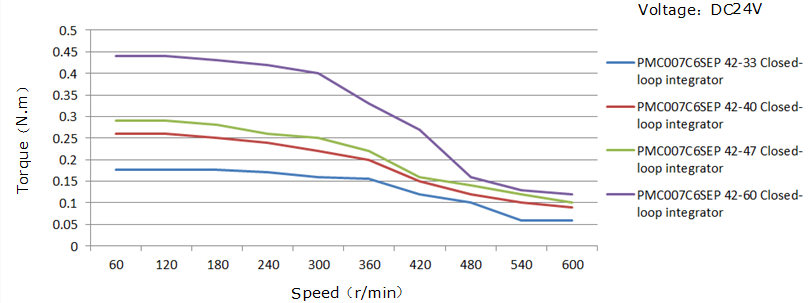

Stepper motors are generally classified according to the phase number, and then the size of the motor is classified. The commonly used sizes are 28, 35, 42, 57 and 86 motors. For example, the most commonly mentioned 57-76 stepper motor means that the width of the motor is 57 mm, the length is 76 mm, and the left is 42 step drawings. The larger the size of the motor is, the greater the output torque is at the same speed; the running speed of the stepper motor is not constant, so the speed of the stepper motor is not constant. There is no rated power, and the output torque of motor shaft decreases with the increase of rotational speed. General motor manufacturers will have the frequency curve of this motor, as shown in the right of the following figure. So we need to provide the application scenario on the equipment when selecting the model. If we can provide the application speed and the required torque accurately, we can quickly select the size of the motor.

Driver selection:

The choice of stepper motor driver is generally decided by the upper control system. Compared with the traditional driver, it only has the function of pulse amplification and needs the upper computer to send out the pulse signal. At present, the products with more technical content on the market are generally integrated products of drive and control. With the small stepper motor driver, the bus input signal can be received while amplifying the pulse. The sub-controller function can write some simple control programs to be executed offline, eliminating the upper computer. If the number of axles on the device is large and the motor is required to respond quickly, the driver driver controller of the small stepping motor is generally recommended. Therefore, when choosing the driver, it is necessary to provide information such as the number of axes of the device, the relevant control requirements and the model of the upper computer.

Whether to connect encoder:

The so-called open-loop control is a stepping system without an encoder. Whether or not it achieves the desired control effect, the motor will rotate according to the existing instructions, which will lead to inaccurate control. The general control accuracy requirement is not particularly high. The stepping system with an encoder is a closed-loop stepping control, and the encoder can monitor the rotation of the motor shaft in real time and send the message. The controller adjusts the driving current according to the feedback signal. It can prevent step loss and make the output torque of the motor bigger. At the same time, it can also make the stepper motor achieve higher speed.

As shown in the following figure, a highly integrated stepping control system integrates motor, encoder and drive controller, which greatly reduces the volume of stepping system and optimizes the system step line.