- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

How to Choose the Appropriate Stepping Motor for AGV Car?

The AGV is called Automated Guided Vehicle and can also be called Laser Guided Vehicle (LGV). In Germany, the technology is also known as the Fahrerlose Transport System (FTS) and the Swedish förarlösatruckar. Lower cost AGVs are often referred to as automated guided carts (AGCs) and are typically guided by tape. The AGC is available in a variety of models for moving products on assembly lines, transporting goods throughout the factory or warehouse, and providing goods.

Therefore, what kind of motor is selected as the core component is extremely important.

First of all, the AGV trucks are mostly self-propelled and driven by batteries, so the voltage of the drive motor is mostly DC24V or DC36V.

Secondly, the AGV truck cannot be snaked when it is straight ahead along a given track, so the speed change rate of the motor should be kept at a low level.

In addition, the AGV truck uses a miniaturized, low-profile design in practice. Therefore, the motor should save space as much as possible on the basis of small size and high power.

Therefore, the stepping motor that is conventionally used on the market is to be removed.

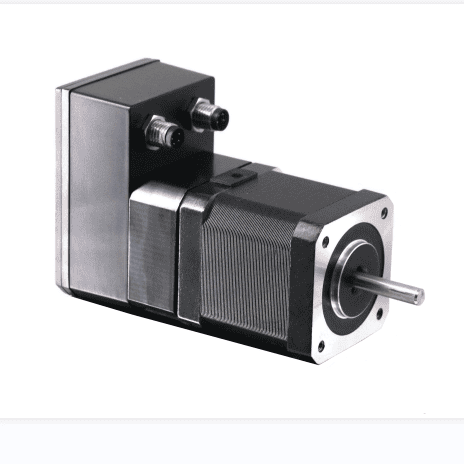

At present, in order to solve the space problem, the AGV uses the most integrated stepper motor integrated with the PMC007 small stepping motor driver solution provided by Chongqing Spectrum. This integrated stepper motor driver, encoder, stepper motor in a new stepper motor, not only solves the volume problem of conventional stepper motor, but also solves the problem of precision that has plagued engineers for many years.