- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

difference between electric cylinder and electric push rod

The electric cylinder and the electric push rod are generally called the electric actuator, which drives all kinds of screws to rotate through the motor, and transforms the nut into a kind of reciprocating straight-line motion of linear motion. Generally speaking, the principle of the electric cylinder is the same as the working principle of the electric push rod, which is the motion of straight line push-pull and lifting, but strictly speaking, there are many subtle differences between them( In English, they are collectively referred to as electric linear actuator, and they are not specially distinguished. The differences between electric cylinder and electric push rod are specifically analyzed as follows:

1.Structure

The nut inside the electric push rod is a common nut with large internal structural clearance. The motors used are mostly AC and DC motors, so the repeated positioning accuracy is low and the service life is short.

The structure of the electric cylinder is a screw rod structure. Most of the electric cylinders are servo motors or stepping motors, and the internal knot gap is almost zero. Therefore, the electric cylinder has high precision of repeated positioning, more extensive application and long service life (the total stroke can reach more than 1000000km).

2.Precision:

Precision of AC electric push rod: 0.2mm, DC electric push rod: 1-2mm

Precision of electric cylinder: 0.01-0.02mm

3.Material selection

The electric push rod is made of ordinary trapezoidal lead screw and ball screw. It is usually connected with gear motor and turbine rod for transmission, with low efficiency;

The servo electric cylinder is usually made of grinding ball screw and planetary ball screw. It is directly coupled with the motor, or synchronously connected with the pulley, with high speed and efficiency.

4.Speed:

The speed of electric push rod is generally less than 100mm / S

The speed of electric cylinder can reach 2m / S

5.Control

The electric push rod can only control two positions, i.e. 0 point and end of travel;

The electric cylinder can be started and stopped at any position.

6.Thrust

The electric push rod is mainly used to push and pull, and the thrust is difficult to exceed 10 tons; Electric cylinders, such as servo electric cylinders, have a thrust of 35 tons or more.

Generally speaking, the electric push rod is simple in structure, small in thrust, low in working system, simple in control program and low in price. It is used as executive machinery in all kinds of simple or complex technological processes. The electric cylinder, especially the servo electric cylinder, has the characteristics of high thrust and long travel, accurate speed, position control, high speed and higher in price than the push rod, so it is widely used.

The above is the difference between the electric cylinder and the electric push rod.

The common motors of small power electric push cylinder and electric push cylinder are as follows:

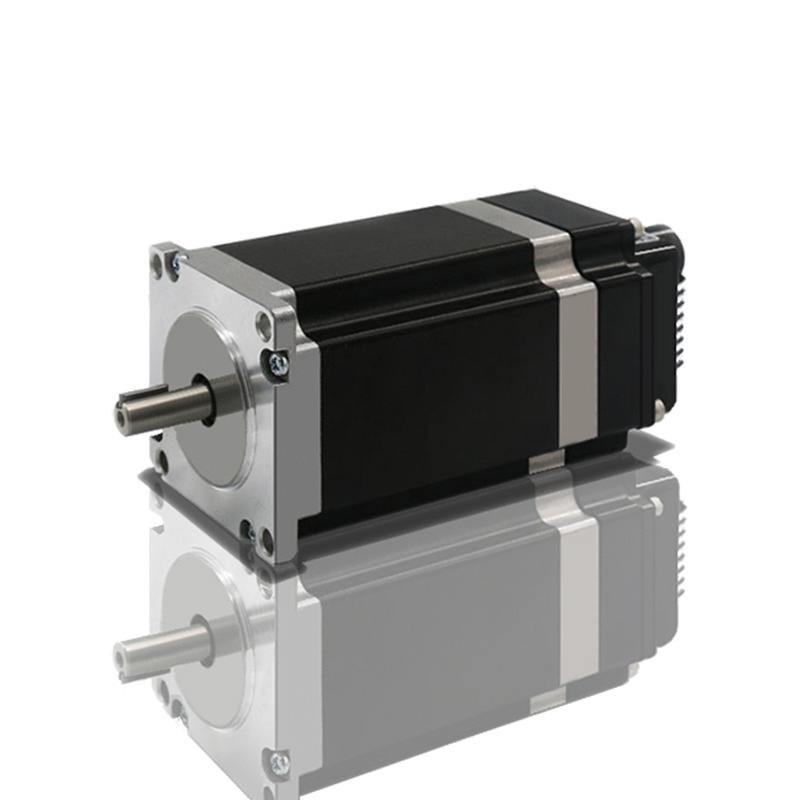

We hope it could help you to choose our product: integrated stepper motor, stepper motor controller, stepper motor driver.

Origin: en.pusirobot.com