- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Comparison of motor can bus control and pulse control

1. Synchronicity

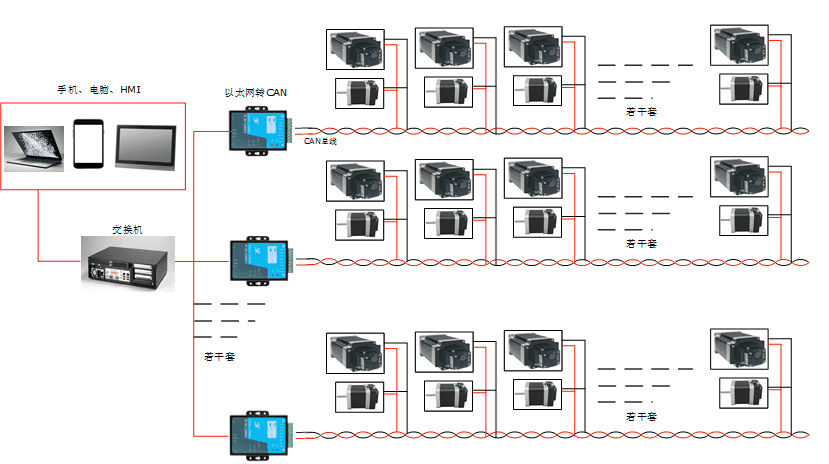

Can bus type: Because the bus signal transmission rate is up to 1M, the synchronization error of multiple motor control can reach microsecond level, almost no synchronization error.

Pulse type: Because the pulse type is that the controlling-terminal sends the pulse signal directly to the driving-terminal through the cable, which will cause the out of step in the pulse transmission process. In addition, the limited pulse transmission speed will cause the signal delay, so the possibility of multi axis out of sync is higher. The longer the cable, the more the motor, the worse the synchronization.

2. Wiring set step

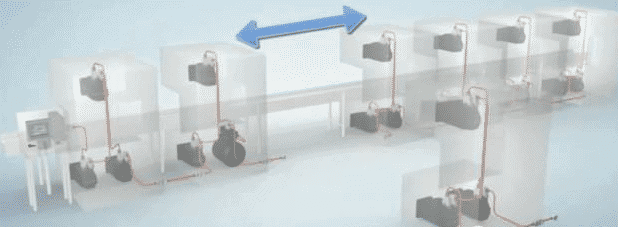

Can bus type: The bus type wiring is very simple, PLC and other upper computers only need to connect two wires to complete the control wiring of dozens or even hundreds of motors, simplifying the difficulty of wiring set steps, making the layout of wiring easier and saving wire at the same time.

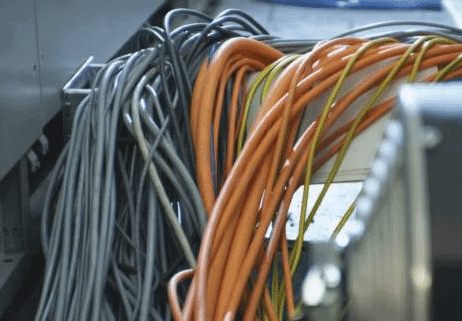

Pulse type: Generally, the pulse type is directly connected to the terminal motor by the upper computer such as PLC. Normally, there are 4 pulse lines for each motor. If 25 motors are used on a set of equipment, only 25 motor control interfaces are needed on the PLC, and 100 cables need to be connected, which will make the whole control system extremely complex, not easy to system step, affecting the perception of the equipment and wasting wires at the same time.

3. Immunity

Can bus type: Only two signal wires are needed for bus control, and the signal wire can be twisted in pairs. In addition, the cable with shielding layer can be used to achieve strong anti-interference.

Pulse type: The anti-interference ability of the pulse signal transmitted by the pulse type control cable is weak. The longer the signal transmission cable is, the more the number of motors is, the weaker the anti-interference ability is, and the abnormal operation of the equipment is easy to occur.

4. Scalability

Can bus type: Bus control can be configured as multiple networked control stations, whether it is a slave station such as motor drive or a master station such as PLC. These reserved interfaces can be configured, which is helpful for the increase of later functions or the change of control mode.

Pulse type: The pulse type control has been limited in the hardware interface and cannot be configured. It will be very difficult to add functions or change the side control mode in the later stage.

The above four points are the main differences between CAN bus control and pulse control.

Hope it will be helpful for you to choose our product, integrated stepper motor, stepper motor driver and stepper motor controller.