- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

How To Increase The Torque Without Changing The Mounting Size of The Motor

When upgrading the current equipment, we often require more load, higher speed, faster running time. However, limited by the space structure, the mounting size of the motor cannot be changed. So, how to increase the torque without changing the mounting size of the motor?

There are many factors that affect the torque. This time we selected four of them to explain.

1. Number of coils

2. Driving current

3. Clearance between rotor and stator

4. Driving mode

This time we will focus on the analysis of the influence of coil number and driving current on motor torque, and put forward the scheme of increasing torque

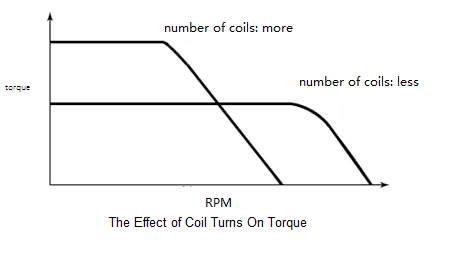

The Effect of Coil Turns On Torque

The torque of stepping motor is related to the number of coils. The more coils are, the larger the torque is when start-up, but the torque will be small at high speed. The smaller the number of coils, the smaller the torque when start-up, but compared with the number of coils, the torque will be large at high speed.

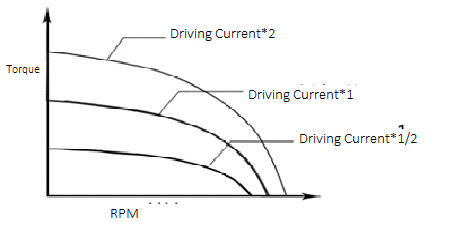

Effect of Driving Current On Torque

The torque of the stepping motor is proportional to the driving current. The greater the driving current of the motor, the greater the output torque of the motor.

However, the larger the driving current is, the greater the heating capacity of the motor is. Therefore, the input current cannot exceed the rated current value.

According to the above content, combined with the proposition of increasing torque without changing the installation size of the motor, the following solutions can be considered

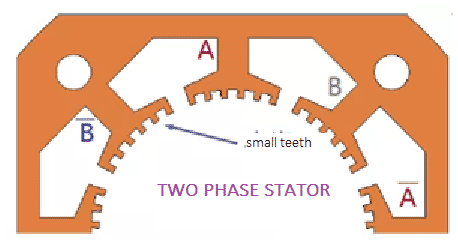

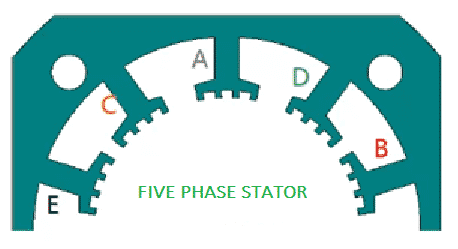

1、 Different torque characteristics of 2-phase / 5-phase stepping motor

The structure of 2-phase stepping motor is different from that of 5-phase stepping motor. The number of small teeth on the stator of 2-phase stepping motor is more than that of 5-phase stepping motor, which has stronger magnetic attraction to the rotor. And 2-phase stepping motor has more space to coil, so the torque of 2-phase motor is higher than that of 5-phase motor at low speed.

The figure below shows the torque characteristics comparison of 2-phase / 5-phase stepping motors with the same installation size.

When selecting products, 5-phase products can be selected in high-speed section and 2-phase products can be selected in low-speed section. But on the market, two-phase stepper motor is commonly used, and five phase stepper motor will not be used in non special cases.

2、 Select high current products

The torque can be increased by using products with higher driving current.

Taking our PUSI brand PMC007C6SXP series closed-loop integrated stepping motor as an example, different torque output can be obtained by setting different phase current. The larger the current is, the larger the torque output is.

Although the driving current of the motor increases, the torque will increase accordingly. But in contrast, the heating capacity of the motor will also increase. Too high temperature will lead to the insulation deterioration of the motor coil and shorten the life of the motor. Therefore, in the design and use of products, it is necessary to consider the heat output and set the driving current within a reasonable range.

We hope the above content will be helpful for your to choose our stepper motor driver/ stepper motor controller and integrated stepper motor.