- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Application of multi-turn absolute encoder stepper motor in the glue injection industry

A valve is a mechanical device that controls the flow, direction, pressure, temperature, etc. of the flowing fluid medium. The valve is a basic component in the pipeline system. Valve fittings are technically the same as pumps and are often discussed in a separate category. Or the handwheel, handle or pedal operation can also be controlled to change the pressure, temperature and flow rate of the fluid medium. Valves can perform continuous or repeated operations on these changes, such as safety valves installed in hot water systems or steam boilers. In more complex control systems, automatic control valves are used according to the need for external input (that is to adjust the changing set point of the flow through the pipeline). The automatic control valve does not need manual operation according to its input and setting, so that the valve can accurately control the volume requirement of the fluid medium. Valves are also divided into cast iron valves, cast steel valves, stainless steel valves, chromium molybdenum steel valves, chromium molybdenum vanadium steel valves, duplex steel valves, plastic valves, and non-standard customized valve materials.

Today we mainly introduce to you an automatic valve control scheme based on stepper motor control.

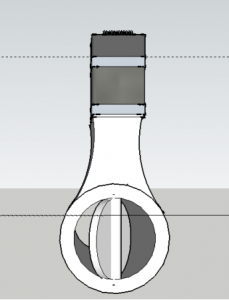

In recent years, with the rise of a series of mobile phone giants such as Apple, Huawei, Xiaomi and the automation upgrade of the notebook industry, a series of 3C electronics processing industries represented by Foxconn have developed rapidly. As the manufacturing processes of mobile phones and laptops become more and more demanding and more sophisticated, the key assembly parts of the production line urgently need to be upgraded. Such as glue injection, valve control system for glue injection.As shown below:

The general valve stepping control system is limited by the relatively compact valve's own mechanism, so most of the mechanisms do not have a reasonable zero sensor installation position at all, which leads to the supply of many valve groups to be made on the mechanical structure Very large changes, time-consuming, labor-intensive and cost-intensive, and some even sacrifice the efficiency of the valve. There are also some control valves. The glue injection system requires very high glue injection accuracy, so the control accuracy of the stepper motor is required, because the general stepper motor will lose step and overshoot during the load increase and speed increase process. The problem is that the current motion control system of stepper motors does not support the functions of feedback and accuracy correction, so the accuracy of glue injection and potting has not been greatly improved. Aiming at these two points, the existing solution in the industrial control market is to install a multi-turn absolute encoder at the end of the motor. One is to record the moving position of the motor after power failure, but to feed back the corrected motor during the motor rotation. Accuracy. However, most multi-turn absolute encoders are installed separately, which cannot meet the user's high-humidity use scene, and has certain limitations in use. The motor is as follows:

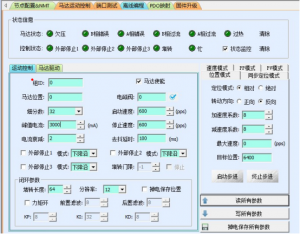

Therefore, in order to respond to the needs of the majority of users in the industrial control market, PUSIROBOT has launched an integrated multi-turn absolute closed-loop waterproof stepper motor on the PMC007 series of motion control platform independently developed. In addition to inheriting the multiple motion control methods of PMC007, this motor As shown below:

The M12 aviation plug is used, and the waterproof effect is above IP65, which is more suitable for operation in high humidity conditions.

In addition to eliminating the need for sensors during valve operation, the multi-turn absolute encoder can save users the trouble of optimizing the valve structure. The power-down memory position function can support the motion control system to continue power-off for more than 60 days. Support the movement of the number of laps within the 16th power of memory 2. It can avoid the manual reset operation of the factory after the equipment is powered off.