- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Classification of stepper motor gearbox

When stepping motors require high torque at low speeds, we will choose gearboxes. Reduce the speed through a gearbox with a certain reduction ratio, while increasing the torque by a certain ratio. The gearbox is a mechanism that uses a gear speed converter to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque. Then the classification and selection of the gearbox is very important.

Worm Gear for Step Motor

The characteristics of the worm gear is relatively large size, not compact enough, self-locking under certain conditions, relatively low efficiency, about 60%. Because the efficiency is relatively low, it cannot be satisfied in many occasions, and it is generally not recommended to use it with a stepper motor.

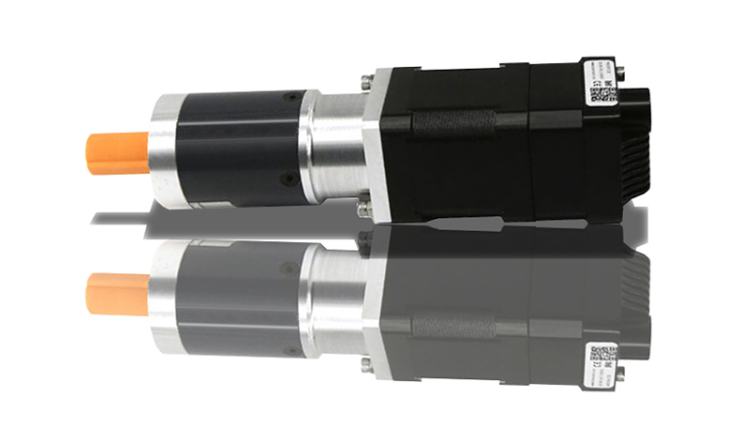

Planetary gearbox for stepper motor

Planetary gearbox, as its name, revolve around the star. There are three planetary gears rotating around a sun gear. Planetary gearbox has the characteristics of high strength, small size, low noise, low price, large transmission torque, long life, and high transmission efficiency, which is probably above 80%. Puse integrated motor and planetary gearbox are widely used in textile, packaging, pharmaceutical, paper, woodworking, electronic instrumentation, medical, environmental protection and other mechanical equipment fields. Pulse closed-loop stepper reducer provides optimized industry solutions to help Equipment optimization in various industries.

Harmonic gearbox for stepping motor

The harmonic gearbox is mainly composed of four basic components: a wave generator, a flexible gear, a flexible bearing, and a rigid gear. The harmonic drive gearbox is a flexible gear that is equipped with a flexible bearing to make the flexible gear produce controllable elastic deformation. Gear transmission that meshes with rigid gears to transmit movement and power. It is characterized by high reduction ratio, small backlash, small size and high efficiency, but it is expensive and suitable for equipment with strict requirements. In general, it is recommended to use a stepping motor with a planetary gearbox. For example, the integrated motor is used in papermaking equipment, and it can be used stably under the condition of long-term high-speed operation, bringing customers a "zero defect" experience.