- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Summary of Capacitive Liquid Level sensor controller Problems

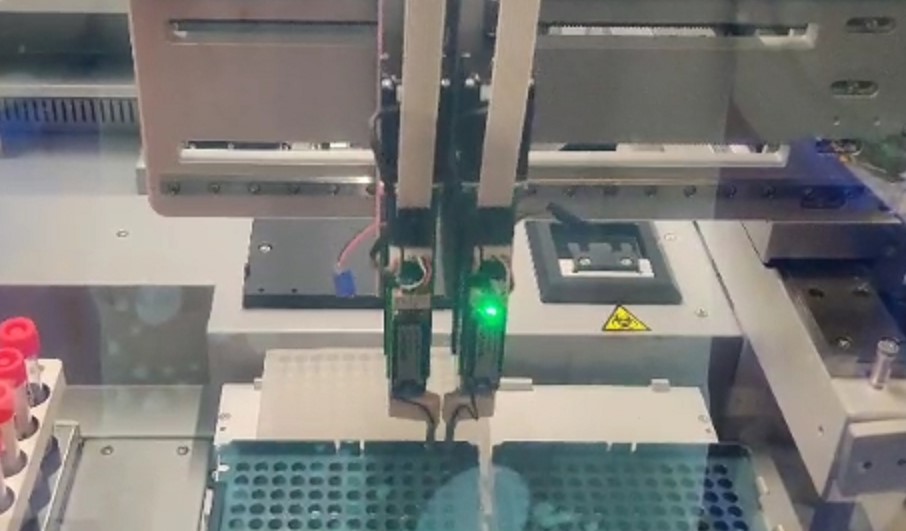

Liquid level detection has almost become a necessary function in the field of fully automatic medical equipment. In the process of sample addition and pipetting of fully automatic medical equipment, it is necessary to detect whether the probe touches the liquid surface of the reagent, as the equipment system enters the next step. Basis.

Therefore, how to ensure the orderly, stable, and efficient work of multi-channel liquid level detection in IVD equipment has become a focus and difficulty of the research and development personnel of fully automatic medical equipment.

In the article "Medical Equipment Liquid Level Detection: Capacitive Liquid Level Sensors", the difference and advantages of liquid level sensors compared with traditional liquid level detection solutions have been introduced in detail, and they have been recognized by the majority of IVD industry equipment manufacturers. What we introduce to you is the problems our users and friends encountered in the production process of equipment from sample to batch application. For your reference.

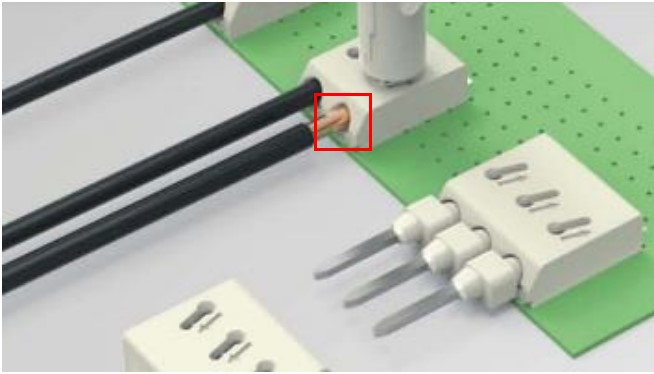

Q: How is the PCS0902 liquid level detection module wired, and how should the wiring be fixed?

The communication port of the PCS0902 liquid level detection module generally uses round cold-pressed terminals; when taking the wire, you can insert a narrow-blade screwdriver into the hole above the connector and squeeze the spring leaf. Pulling the wire harness forcibly may damage the spring.

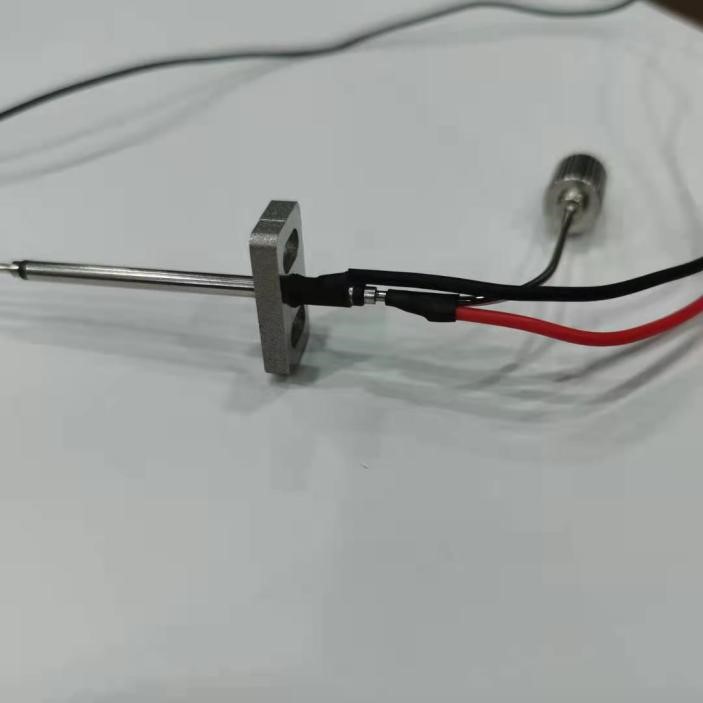

Q: How are double-layer probes and single-layer probes wired?

When the probe is a double-layer needle, the outer layer of the probe is generally connected to the shielding layer of the coaxial cable, and the rack also needs to be connected to the negative electrode of the liquid level module; when the probe is a single-layer needle, the probe can be directly connected It is connected to the inner core wire of the coaxial cable without connecting the shielding layer.

Q: When fixing the probe, how should I choose the material for fixing the probe?

When fixing the probe, in order to reduce the influence of the fixed module on the capacitance value during detection, it is recommended to choose a polyimide material (PI) with a low dielectric constant for the fixing material, which has a high heat resistance value (above 400℃) And high insulation, it belongs to F to H class insulation.

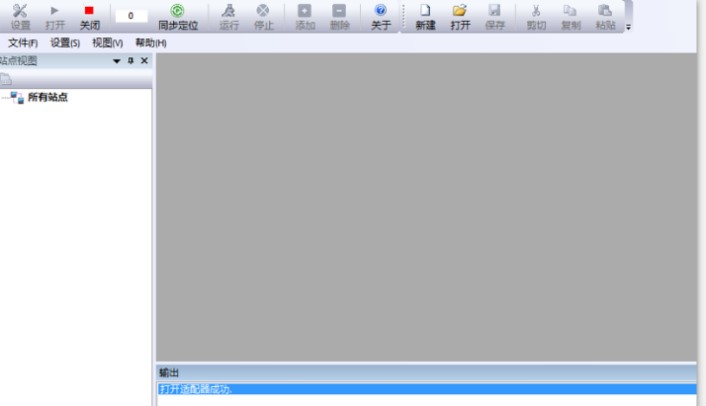

Q: On the PUSICAN debugging software, after clicking "Open", the site is still not scanned. How can I troubleshoot the cause?

First of all, we need to confirm whether the signal line of the liquid level module is correctly connected to the converter; secondly, the baud rate between the USB to CAN adapter, the liquid level detection module, and the PUSICAN debugging software also needs to be consistent; when there are multiple liquid levels When the module is networked, the baud rate on the same CAN bus also needs to be consistent. The default baud rate of the liquid level module is 125Kbit/s when it leaves the factory.

Q: In the PUSICAN debugging software, after double-clicking the scanned site, why the capacitance sensor control interface still does not display the capacitance value waveform?

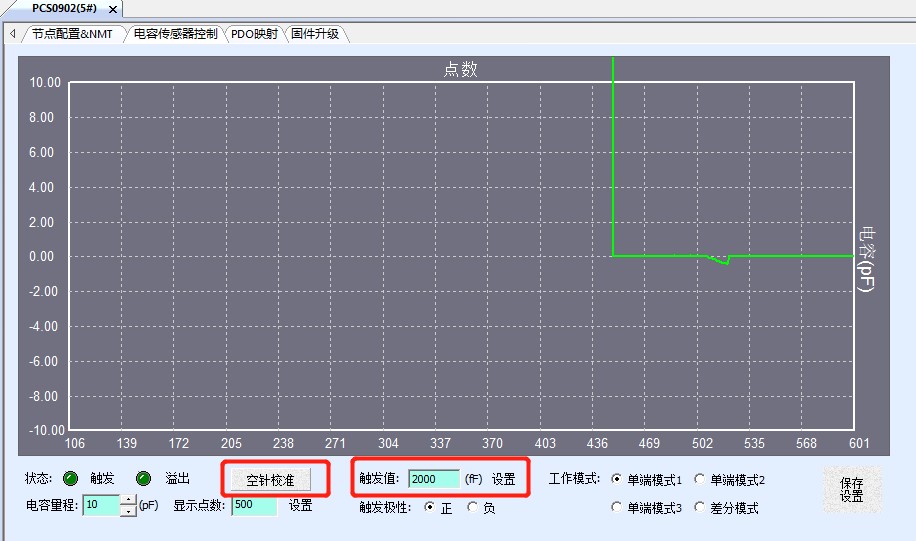

When in use, you need to set the "Trigger Value" and click "Set", and then click "Empty Needle Calibration", the waveform can be displayed. The factory default trigger value of the PCS0902 liquid level detection module is 2000fF, and the setting can be changed according to the detected capacitance value and saved after power-off. There is no need to repeat the setting every time the power is turned on.

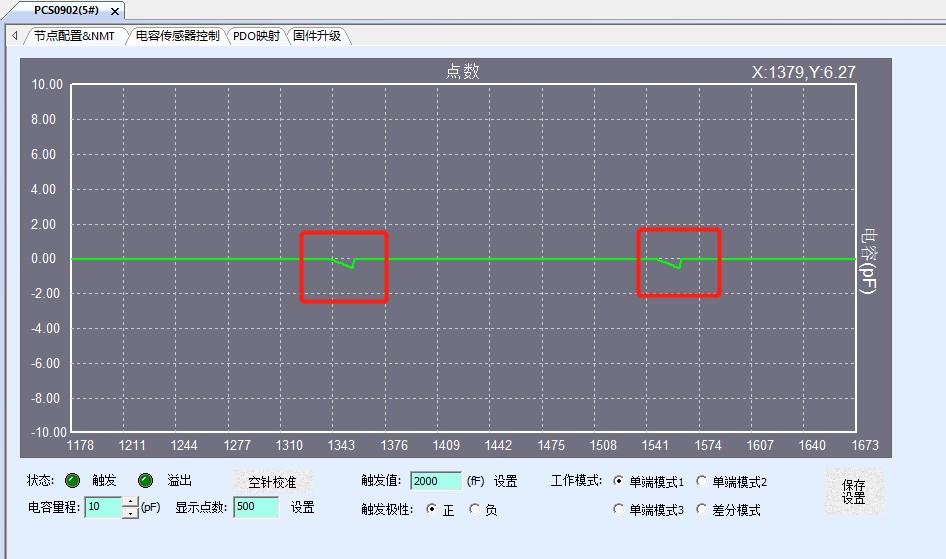

Q: When the PCS0902 liquid level detection module detects the liquid level, it finds that a capacitance value waveform sags every fixed period. Will this affect the detection effect?

When the liquid level module detects, the sags that appear periodically will generally not affect our detection effect. When the capacitance value of the detected liquid is less than 200fF, the waveform sag at this time may affect the detected capacitance value.

Q: After the liquid level module is powered on, it keeps reporting the capacitance value data, how should it be turned off?

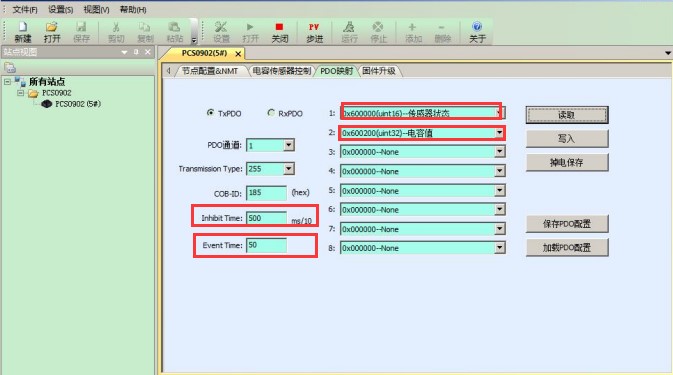

The capacitance value data upload can be turned off autonomously. In the PDO mapping interface of the PUSICAN debugging software, all objects can be set to None, inhabit time and event time are set to 0, and the automatic upload of capacitance value data can be turned off.

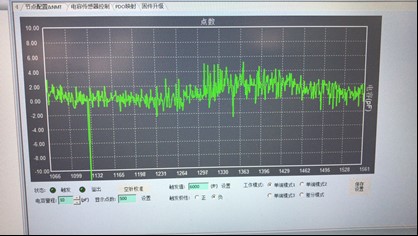

Q: When the PCS090 liquid level module detects the liquid level, the capacitance value curve returned by the empty needle state fluctuates greatly, and the capacitance value curve returned when the probe touches the liquid surface fluctuates slightly, resulting in insignificant changes in the capacitance value curve before and after detection. What are the possible factors that affect the capacitance curve at the time?

When the liquid level module is tested on the equipment, it is affected by the working environment and there are many interference factors, but we can roughly investigate according to the reasons listed below, or contact our after-sales personnel for relevant technical assistance.

- Module power supply, the liquid level detection module is generally recommended to use a regulated power supply to supply power separately;

- The probe is fixed, the probe is recommended to be fixed with a material with a low dielectric constant (polyimide);

- Probe type, suitable probe type can be selected according to different working conditions, generally double-layer needles are used, and the anti-interference ability is better than single-layer needles;

- Whether the wiring between the coaxial cable and the liquid level module and the probe is loose;

- System pipeline, when there is liquid in the system pipeline, it is recommended to disconnect the probe pipeline from the back-end pipeline of the probe with a valve;

- Probe fluid path, when the front fluid path of the probe is connected to the rear fluid path, the cleaning fluid in the front fluid path of the probe and the detection fluid level need to be separated by an air column;

- High-power interference;

- Whether there is any residual liquid at the front of the probe;

This article mainly summarizes the conventional working conditions frequently encountered by engineers in the test process, on how to make the PCS0902 liquid level detection module more obvious waveform changes before and after the equipment is interfered with. In the article "Capacitive Liquid Level Sensor IVD Application Examples" There is a more detailed introduction for future users and friends for further reference. Friends, did you encounter other working conditions when you tested PCS0902? Welcome to communicate with us~