- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Why does the stepper motor vibrate?

The stepper motor can provide precise position control without the need of an encoder by combining small "steps" with a certain rotation angle. However, they show tiny vibrations between steps. Although the vibration cannot be observed in most cases, the vibration does turn into noise, and the noise may be amplified by other mechanisms connected to the motor. Before attempting to correct the problem, it is important to understand the source of the vibration.

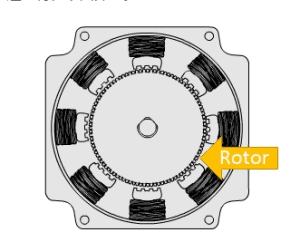

As you can see in the video above, the vibration is not obvious. However, if viewed from a microscopic point of view, it actually shows that each step of the motor is actually overshooting and overshooting. In the video below, we use a 5-phase 0.72° stepper motor to demonstrate its 1-step vibration characteristics and why the stepper motor performs more smoothly at higher speeds. Inside the stepper motor, there is a tiny air gap between the rotor and the stator, magnetic flux flows in it, and the only friction that exists is the ball bearing. When the motor is commanded to move and stop, there is not enough friction in the ball bearing to prevent overrun. This means that due to the inertial force, each step of the motor shaft will be over-adjusted and then down-adjusted. The time it takes for the motor shaft or rotor to stop overshoot and undershoot is called "stabilization time".

In some cases, such as when operating at a resonant frequency, the vibration caused by the step becomes large enough to cause missing steps or excessive noise. The frequency is derived from the relationship between torque stiffness and inertia, and changing any parameter can be outside the operating range of the resonant frequency shift to improve performance.