- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

The application of integrated stepper motor in transmission line inspection robot equipment

The application of integrated stepper motor in transmission line inspection robot equipment

Transmission line inspection plays a very important role in transmission line operation and maintenance. It often brings great difficulties to operation monitoring and maintenance because of terrain or traffic problems. Nowadays, the development of intelligent technology can gradually replace people to go these dangerous places for inspection tasks.

Transmission line inspection robot

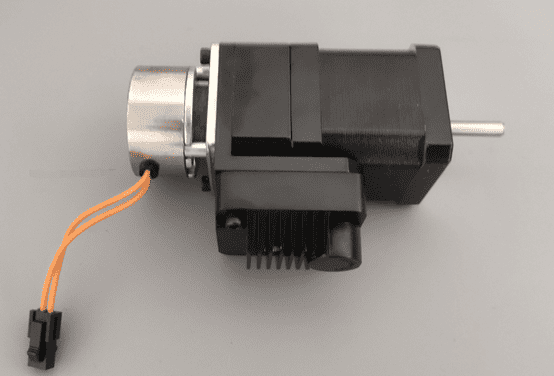

The electric power inspection robot walks on the power transmission cable, and the complicated line climate conditions and electromagnetic environment put forward higher requirements for internal components. In order to adapt to this harsh environment, various new materials have smaller requirements for their own volume, and data feedback must be more accurate. PUSIROBOT 42 integrated closed-loop stepper motor with brake is very good in the control of the lifting and sliding of the pan/tilt due to its small size and high feedback accuracy.

Because the power inspection robot is transmitted to the mobile terminal control center through the wireless module, it is convenient for the staff to analyze and detect the loosening of the corroded bolts on the high-voltage line, the cracking of the insulator, and some hidden safety hazards near the line. The advantage of the CAN bus in the low latency of wireless transmission is also fully reflected, and the staff can analyze in the background in a timely manner to more accurately remotely control the inspection robot.