- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Application of stepping motor in conveying system

Application of stepping motor in conveying system

The use of conveying system in the application of stepper motors is relatively common. There are many kinds of motors on the market. Why do everyone choose stepper motors for structural control? Let's analyze them below.

In fact, the belt mechanism is a low-rigidity mechanism, and gain adjustment is required when using other motors. For example, AC servo motors, AC servo motors have torque control, so you need to make corresponding adjustments according to the load status. Relatively speaking, it is more susceptible to vibration, and when the gain is low, the response is poor. The stepping motor has better synchronization and has no requirement on the rigidity of the mechanism, and can get the movement as set without gain adjustment.

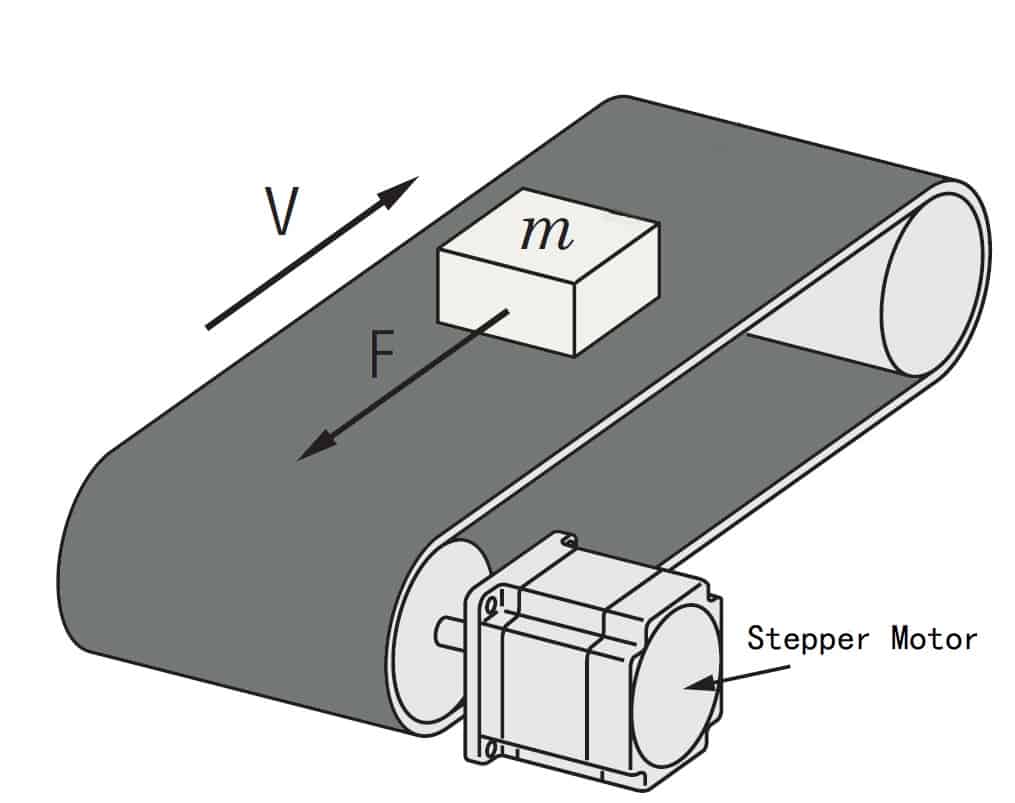

Application of stepping motor in belt structure

The belt structure of the stepping motor is matched with the PMC007 series driver, which reduces the vibration of the motor at low and medium speeds. When running at medium speed to high speed, the torque characteristics are also improved by 30%, and there will be no out-of-step phenomenon, which makes the equipment run more stable and reliable.