- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

PUSI closed-loop integrated stepper motor "lightens the burden" for closed-loop systems

Pusi closed-loop integrated stepper motor "lightens the burden" for closed-loop systems.

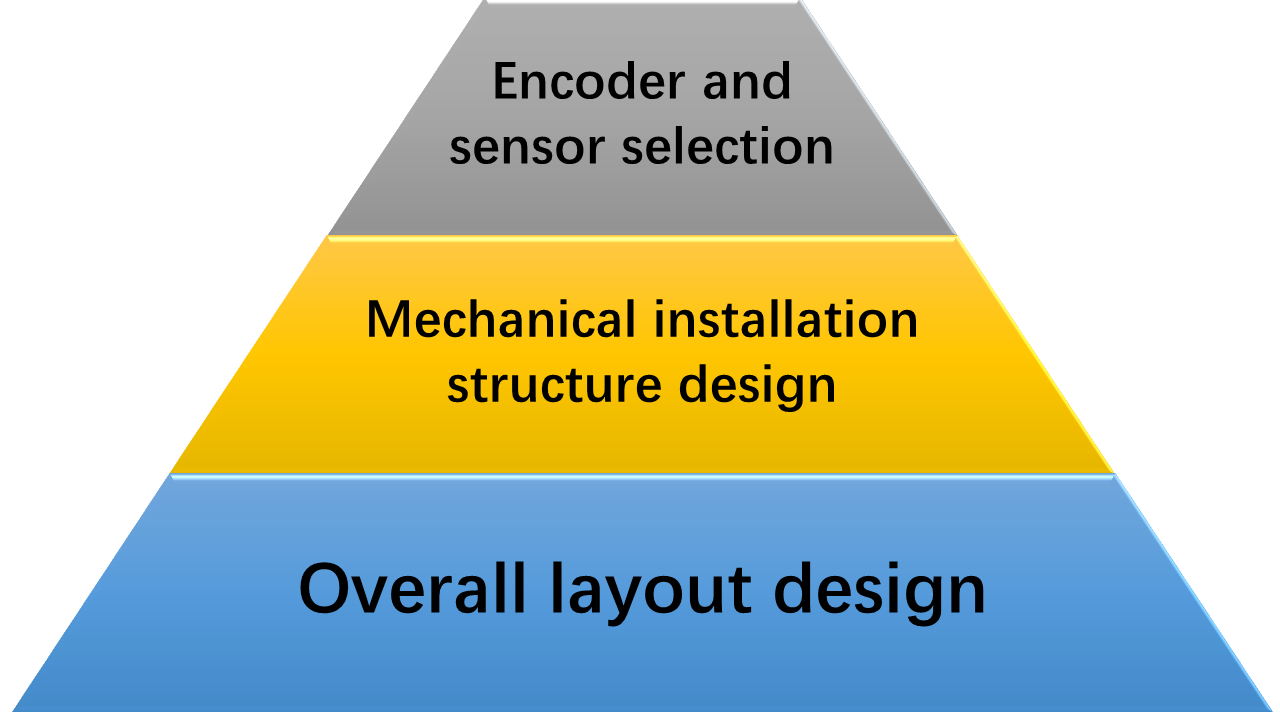

In various application scenarios, in order to improve the accuracy of motor control and improve equipment reliability, the method of installing encoders or sensors is usually adopted. Choosing a suitable encoder or sensor, as well as how to install it, and the rationality of the mechanism design bring a lot of burdens to engineers.

Encoder

Grating ruler

Design issues

When an encoder is installed on a stepper motor, it will increase the design burden. From the selection and use of the encoder/sensor, to the design of peripheral parts and wiring, to the actual design and management, it takes a lot of time.

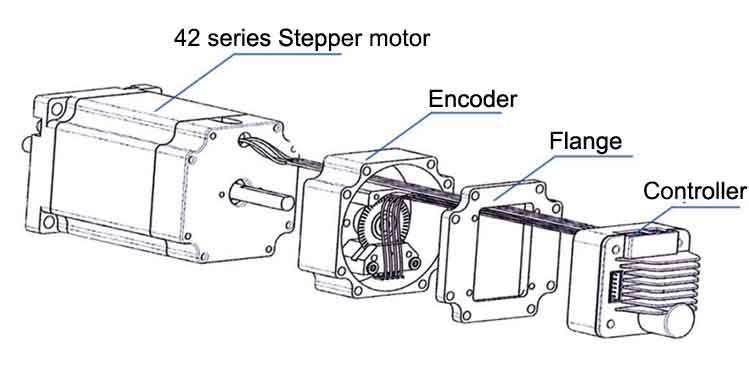

Installation diagram of integrated stepper motor

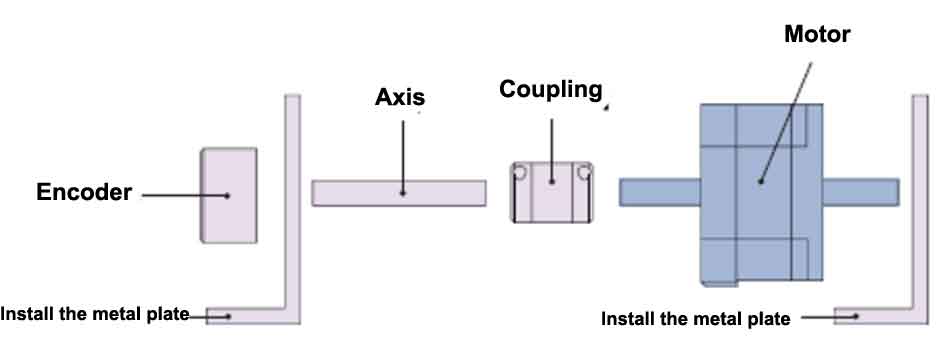

Installation issues

During the actual installation, the installation, calibration, and concentricity adjustment of the encoder (which directly affects the life of the equipment) should also be taken into consideration. The manufacturing and management of the equipment requires huge manpower and material resources.

Installation diagram of integrated stepper motor

The solution

The closed-loop integrated stepper motor of PUSI is self-contained. By integrating the encoder, stepper motor, driver/controller in one step, cumbersome design is eliminated, and the labor cost of design is greatly reduced. This installation method is conducive to the installation and arrangement of single-axis/multi-axis control units, reduces the length of various wires, thereby improving the anti-interference of the unit, and the heat dissipation shape of the controller also makes temperature control simpler and more stable. Considering various factors, such an all-in-one machine is definitely very satisfying when used in large-scale multi-axis applications.