- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

In what use does the stepper motor need a gearbox??

In what use does the stepper motor need a gearbox?

As we all know, gearbox is a mechanical transmission device in many fields, which is an independent component composed of gear transmission, worm transmission, and gear-worm transmission closed in the rigid housing. It is commonly used as a reducer transmission device between the actuator and the working machine, which matches the speed and transmits the torque between the prime mover and the working machine or the actuator. In short, gearbox is a power transmission mechanism, itself does not produce power, its role is to use different gear sizes and speed converters, the number of stepper motor rotation deceleration to their own required number of rotation, and get a larger torque mechanism. So, under what circumstances does the stepper motor need to use the gearbox? PUSIROBOT answers your questions:

Someone may ask, why not directly adjust the speed of the stepper motor? In fact, the stepper motor is directly connected to the equipment, when the equipment is running, the load of the stepper motor will become very large, so that the damage to the motor is also very large, and if the stepper motor is added to the gearbox, it will become different, through the calculation formula:

gearbox speed ratio = input speed/output speed

For example, the reduction ratio of the gearbox is 100, the speed ratio is 100, and the output torque is about 100 times that of the input torque (the speed slows down and the torque increases), when the equipment is running, the load of the stepper motor is only one percent. The integrated stepper open loop/closed loop motor can install the required gearbox at the front or end of the stepper motor.

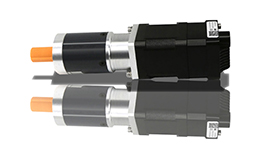

PUSIROBORT integrated closed-loop stepper motor with gearbox

The gearbox is a relatively precise machine, and the purpose of using it is to reduce the speed and increase the torque. It has many kinds, different models, different kinds have different uses, according to the transmission type, it can be divided into gearbox, worm gearbox, planetary gearbox. Its main role:

Reduce the speed while increasing the output torque, torque output ratio = motor output * reduction ratio, but be careful not to exceed the rated torque of the gearbox

The deceleration reduces the inertia of the load