- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

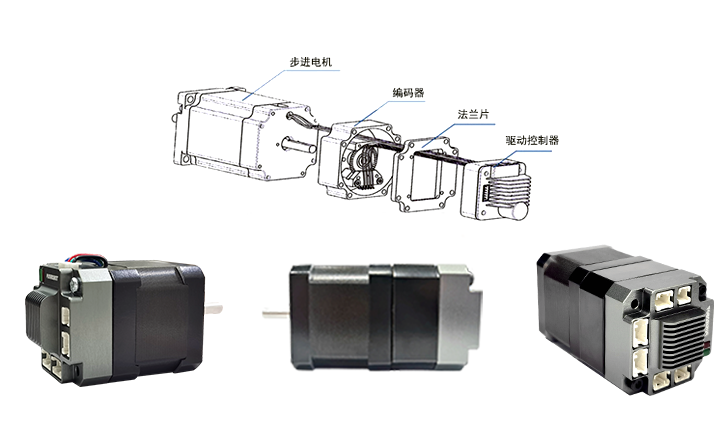

Multi-function stepper motor micro step controller: innovative design and superior performance

With the rapid development of automation technology, stepper motors are becoming more and more widely used in industrial, medical and scientific fields. In order to meet the high requirements of stepper motor control in different fields, we have introduced a new stepper motor micro step controller (PMC006x3) to improve the control performance to meet the needs of accuracy, safety and controllability in different fields.

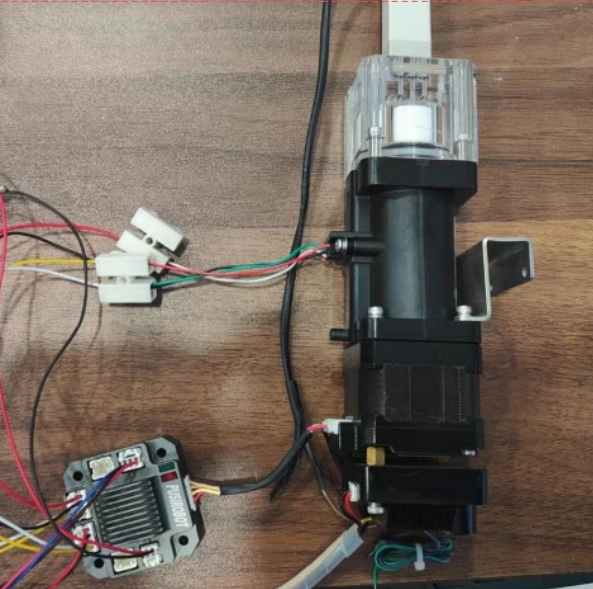

- Multi-function interface design

The stepper motor micro step controller adopts a multi-functional interface design, including different interfaces suitable for various application scenarios, such as communication interface, control interface, sensor interface, solenoid valve interface, etc. Users can choose the appropriate combination of interfaces according to their actual needs to realize the expansion and customization of different functions. - Power reverse connection protection and hot-swap protection technology

To improve the reliability of the system, the controller has built-in reverse power supply protection and hot-swap protection. Reverse power supply protection prevents equipment damage caused by miswiring of the power supply, while hot-swap protection allows users to replace equipment while the system is running without affecting normal operation, ensuring system continuity and stability. - Support 128 micro step accuracy

This interpolation controller supports up to 128 interpolation accuracy, enabling stepper motors to achieve finer and smoother movements through precise current control and micro-stepping technology. This is critical for applications that require high-precision positioning and motion control, such as medical devices and precision instrumentation. - Wide voltage power supply, adjustable current output

The controller supports a wide range of power supply and is suitable for 9-36V power supply, making the power supply adaptation in different working environments more flexible. At the same time, its phase current output can be adjusted from 0.2A to 3A to suit different load and motion requirements. - Multiple control features, intelligent operation

The controller adopts S-curve acceleration and deceleration control, which makes the stepper motor more stable during movement and reduces vibration and noise. At the same time, the drive current is optimized according to the required torque, which also prevents the motor from stalling and reduces power consumption. In addition, two limit switch inputs are supported, which further improves the intelligence of the system. - Solenoid valve/brake control

The controller also supports the control of solenoid valves and brakes, providing users with more flexibility, especially for applications that require stepper motors to brake in motion or change the direction of fluid flow. - Runs silently

Last but not least, the stepper motor micro step controller is designed to operate quietly. The use of advanced control algorithms and motor drive technology improves the smoothness of the current waveform, which helps to reduce the noise sound of the motor when running at high speeds, making it suitable for noise-sensitive environments such as offices and medical equipment.

epilogue

This stepper motor subdivision controller is not only a powerful device, but also a huge improvement in automation systems and mechanisms. Its versatile, safe, and intelligent design makes it ideal for a wide range of applications, driving the continuous advancement of automation technology.