- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

PDO communication: the efficiency core of industrial real-time control

PDO communication: the efficiency core of industrial real-time control

In the field of industrial automation, real-time and reliability are the core requirements of device communication. As one of the key mechanisms in the CANopen protocol, PDO (Process Data Object) has become the cornerstone of real-time control of industrial equipment due to its efficient data transmission mode. This article will provide an in-depth analysis of the working principle, core advantages, and typical application scenarios of PDO.

1. What is PDO?

PDO is a communication object in the CANopen protocol for the real-time transmission of process data, which is designed to transmit critical state information of the device with minimal delay. For example, motor speeds, sensor measurements, switching signals, etc., are transmitted via PDO.

Data characteristics: The amount of data transmitted in a single frame is small (1-8 bytes), but the transmission frequency is high (up to kHz level).

Communication mode: Supports periodic transmission (timed transmission) and event triggering (such as data change or external signal triggering).

2. the working principle of PDO

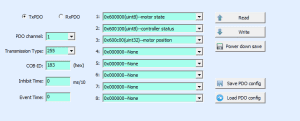

1. Data mapping: from object dictionaries to CAN frames

The core mechanism of PDO is data mapping. Each PDO is predefined in the Object Dictionary (OD) of the device:

- COB-ID: Identifies the CAN frame ID of the PDO and the type of transmission (e.g., broadcast or point-to-point).

- Mapping table: Specifies the location of the data transmitted by the PDO in the object dictionary (such as the "actual location of the motor" in the index 0x600C).

When a transmission is triggered, the device automatically packages the values of these three parameters into 8-byte CAN frames and sends them without software intervention.

2. Synchronous transfer mechanism

In scenarios that require multi-node collaboration (e.g., multi-axis motion control), CANopen uses SYNC messages to synchronize the following topics:

- After the master node sends the SYNC signal, all slave nodes immediately update the PDO data and transmit it to ensure that the data timestamp is consistent.

- Typical application: Cooperative motion control of robot joints to avoid position deviations caused by data delays.

3. Trigger method

- Event Triggering: Sent immediately when a data change exceeds a threshold or an external signal (e.g. E-STOP button pressed).

- Periodic Trigger: Sent at fixed intervals (e.g., 1ms) for steady-state control loops.

- Remote Request: The master node actively requests the PDO data of the slave node by sending an empty CAN frame.

3. The core advantages of PDO

1. Extreme real-time

- No protocol layer latency: PDO data is embedded directly into CAN frames, eliminating the need to encapsulate/parse complex protocol headers.

- Producer-consumer model: Data producers (such as sensors) actively push data and consumers (such as controllers) read directly, reducing the overhead of master polling.

- Typical latency: (at 1Mbps CAN bus rate) for most motion control needs.

- Hardware acceleration: PDO mapping is automatically handled by the CAN controller hardware and does not consume CPU resources.

- Bandwidth optimization: The 8-byte short frame design avoids bus congestion and is suitable for multi-node dense communication scenarios.

- Dynamic remapping: Use SDO to modify PDO mapping relationships at runtime to meet the requirements of different working conditions.

- Transmission mode switching: It can be dynamically configured to be periodic or event-based, balancing real-time performance and bandwidth usage.

4. Typical application scenarios of PDO

1. Motion control system

Step Drive Control:

- TPDO sends feedback on the actual position and status of the motor;

- RPDO receives target position, speed commands, etc.

2. Distributed I/O system

- High-speed acquisition: The digital input (DI) status is uploaded in real time via TPDO (e.g., 1ms cycle).

- Real-time output: The controller issues relay control instructions (such as emergency stop signals) through RPDO.

- Fault alarm: Abnormal device status (such as over-temperature and over-current) is immediately reported through the event-based TPDO.

- Safety link: The safety PLC transmits safety data (e.g. STO signals) via a dedicated PDO channel.

5. Limitations of PDO and countermeasures

1. Data Limit

- 8 bytes per frame: Not suitable for transferring large chunks of data (such as log files).

- Solution: Split the big data into multiple PDOs or use SDO fragmentation for transmission.

- Latency fluctuations at high loads: Multiple PDOs competing buses can cause low-priority frame delays.

- Solution: Optimize the COB-ID priority, and assign a low ID value to the key PDO (the smaller the CAN ID, the higher the priority).

- Fast: meet the requirements of real-time control at the millisecond level;

- Efficient: Hardware-level optimization reduces resource consumption;

- Flexible: Dynamically configure to adapt to complex scenarios.

6. Comparative advantages of CANopen and other industrial communication protocols

Compare modbus

- Real-time

CANopen's PDO communication cycle can be as low as 1 ms (typical), which is much better than that of Modbus RTU (typically more than 10 ms). - Topology

CANopen supports a multi-master bus topology, while Modbus has a master-slave architecture with limited scalability. - Data semantics

CANopen defines the meaning of the data through an object dictionary, which is highly standardized (e.g., the DS402 standard defines motor drive parameters), while Modbus requires custom register mappings.

- Cost and complexity

CANopen is based on low-cost CAN hardware and is suitable for small and medium-sized systems; EtherCAT requires a dedicated slave controller (ESC) and is more expensive in hardware. - certainty

EtherCAT achieves microsecond determinism via a time-slotting mechanism, which is superior to CANopen (for scenarios where higher real-time performance is required, such as high-speed packaging machinery). - Amount of data

CANopen has a limited amount of data per frame (8 bytes) and EtherCAT supports the transmission of large blocks (e.g. vision systems).

- Protocol stack complexity

The CANopen protocol stack is lightweight (suitable for resource-constrained embedded devices), and Profinet needs to implement a complete TCP/IP stack. - Real-time grading

Profinet IRT (Isochronous Real-Time) is suitable for high-precision synchronization scenarios such as printing presses, while CANopen meets most medium-sized real-time requirements via PDO+SYNC. - Interoperability

CANopen's CiA standard device profiles (e.g. I/O modules, encoders) simplify device integration, while Profinet relies on GSD file configuration.

In the era of Industry 4.0, the collaboration between PDO, SDO, and NMT (Network Management Protocol) is promoting the upgrade of real-time communication architecture from stand-alone devices to smart factories. For engineers, a deep understanding of PDO configuration and optimization is a key skill for building highly responsive and reliable industrial systems.