- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Pusi Application Case | Drone Nest

With the continuous development of the drone industry, drones have become an indispensable tool for industrial inspection and data collection due to their flexible field of view and terrain-independent mobility. Meanwhile, drone nests serve as a key support for the efficient operation of drones, effectively addressing many challenges faced during drone flights.

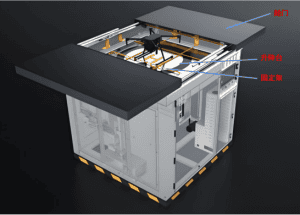

Drone Nest | Equipment Description:

The drone nest is an intelligent ground infrastructure specifically designed to provide automated takeoff, landing, charging maintenance, environmental monitoring, and data management services for drones. The drone nest requires a high-precision, highly reliable, and environmentally adaptable motion control system. With ten years of mature motion control algorithms and a system based on stepping motors, Supsi can quickly and accurately operate stably for extended periods under various complex conditions, effectively enhancing the reliability of the nest.

Drone Nest | Detailed Explanation of the Pusi Solution:

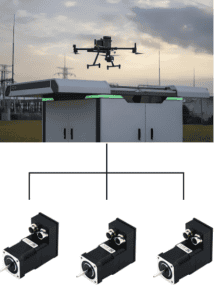

This scheme uses the Spresense PMC007 series - CAN bus - multi-turn closed-loop aviation connector integrated machine, which can synchronously and accurately open the hatch and elevate the lift rapidly under actual working conditions, and the IP65 protection level is sufficient to support adaptation to various usage environments.

The PMC007 series has become an ideal driving solution for the automation functions of drone nests due to its exceptional precision, high reliability, good cost-effectiveness, and strong environmental adaptability. Its advantages in simplifying system design, reducing maintenance difficulty, and enhancing long-term stability particularly meet the demands of large-scale, high-frequency operations of drone swarms.

Features of the PMC007 series closed-loop aviation plug integrated machine:

- Block switch detection, high-speed high torque

- Offline programming: No need for a host computer

- Multiple loops without missing steps or losing power memory location

- IP65 protection rating

- Supports operation at low temperatures of forty degrees.

- Supports standard Modbus/Canopen protocols

- Connecting network and synchronous start-stop