- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Medical equipment liquid level detection solution: capacitive liquid level sensor controller

Liquid level detection has almost become a necessary function in the field of fully automatic medical equipment. In the process of sample addition and pipetting of fully automatic medical equipment, it is necessary to detect whether the probe touches the liquid surface of the reagent, use this as the basis for the equipment system enter to next step. In order to improve the detection speed, most of the current IVD instruments use multi-channel liquid level detection to improve the efficiency of the system. The liquid level detection function of the equipment will be used thousands of times in the daily work. Once the liquid level detection has any deviation There will be abnormal operating conditions of equipment such as firing needles and reagent cross-contamination. How to ensure the orderly, stable and efficient work of multi-channel liquid level detection has also become a focus and difficulty of the research and development personnel of fully automatic medical equipment.

At present, most IVD equipment manufacturers with self-developed capabilities use TI's liquid level detection chip to build their own liquid level sensor modules. This method has the following problems:

• The detection accuracy is general, which is easy to cause EMI problems

• Can’t handle specific medium and scenes, such as blood clotting, air bubbles, hanging beads

• only suitable for general-purpose platforms, and cannot be adapted to special rack structures

• Unable to flexibly adjust the detection range and accuracy

• Can't adapt to multiple different reagents and testing needles

• Need strong R&D strength, high comprehensive development cost, long time period

The PCS0902 capacitive liquid level sensing controller provided by Chongqing Pulse Robot Control System Co., Ltd. uses a software algorithm solution instead of an integrated chip, which can provide a complete solution for IVD medical equipment, environmental protection equipment and other liquid level detection.

PCS0902 liquid level sensor controller overview:

• PCS0902 is a programmable capacitive sensor controller with high cost performance and simple and flexible interface

• This series of controllers can detect capacitance changes below 1pf, and can convert the detection results into IO level output and intuitive LED instructions

• PCS09xx provides a simple and quick control command set, which can be connected to the control host via CAN and read the measured value directly

• Suitable for various medical, environmental protection, laboratory instruments reagent level detection, container level detection and other application scenarios.

For the two solutions mentioned above, here is a comparison of related technical performance and indicators

Program overview:

PCS0902 capacitive liquid level detection module adopts processor and software algorithm.

The integrated chip solution uses a dedicated integrated chip from TI company.

Real-time graphics detection:

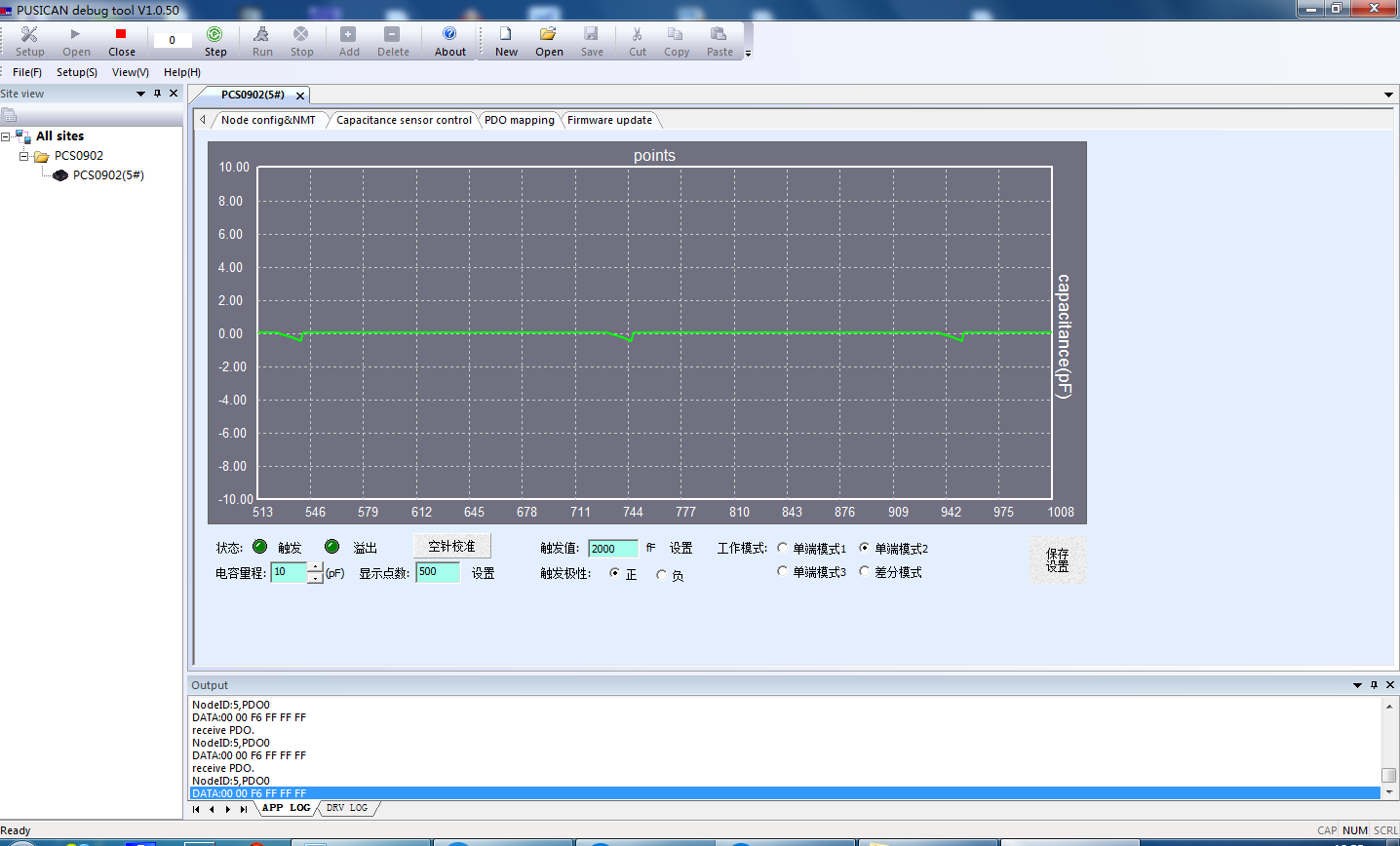

PCS0902 is equipped with special computer debugging software. Click "Capacitance Sensor Control" on the main interface to enter the real-time monitoring interface of capacitance value. After entering this interface, the capacitance value will be displayed on the interface as a waveform diagram. At the same time, the working mode, trigger mode, etc. Set the parameters, the interface is as shown in the figure below

Integrated chip solution has no real-time monitoring interface

Response speed and detection accuracy:

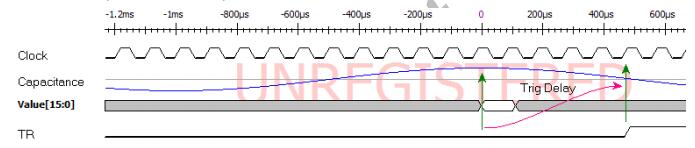

For high-precision experimental testing equipment, the accuracy and response speed of liquid level detection are three important indicators. The PCS0902 controller uses a high-speed processor to execute control routines and filtering algorithms, and reduces the response time to the us level while ensuring detection accuracy and false alarm rate. As shown below. At the same time, in order to reduce the antenna effect caused by the reagent needle (one of the main defects of the inductive resonance measurement method) and reduce electromagnetic radiation, PCS0902 limits the excitation frequency to less than 10khz.

In order to achieve better EMC performance, the response speed of the integrated chip solution must be controlled above the typical value of 2ms.

Anti-interference ability:

In the thousands of triggers of multi-channel liquid level detection, even if the external interference is small, it is likely to cause abnormal operation of the equipment. It is necessary to ensure the stable and orderly operation of multi-channel liquid level detection. The anti-interference requirements of the liquid level detection sensor will be very high.

The PCS0902 capacitive liquid level detection sensor can read the distributed capacitance and frequency characteristics of the rack, medium, probe, etc. through software according to the actual working conditions of the equipment, and then configure the relevant parameters to improve the sensor's anti-interference ability and achieve flexibility in special environments response.

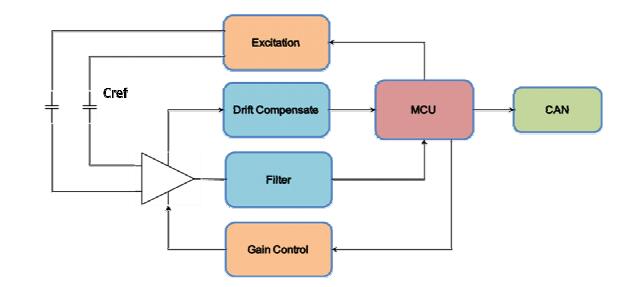

In order to obtain better detection accuracy and stability, the PCS0902 controller uses digital signal processing technology to control the measurement loop, as shown in the figure below. The external environment of the system (stable, humidity) and the connection method have a significant impact on the system reference capacitance value. The software method can eliminate this kind of influence very flexibly.

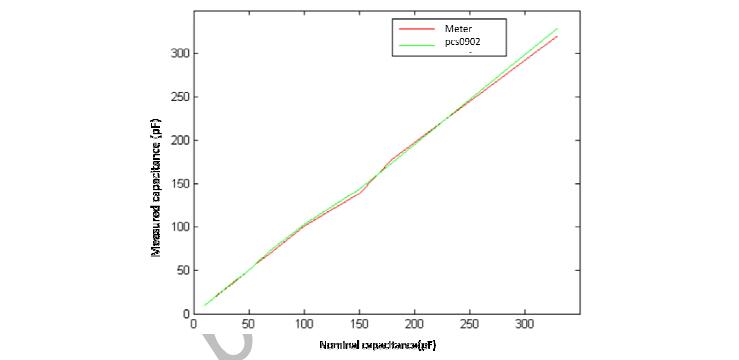

The built-in control algorithm of the PCS0902 sensor can ensure the linearity of the measurement, as shown in the figure below, to the greatest extent from the influence of these environmental factors, but the user may need to compensate the basic capacitance value according to the situation.

The integrated chip solution is a fixed general anti-jamming measure, and there is no anti-jamming countermeasure under special working conditions.

Model adaptation:

PCS0902 capacitive liquid level detection sensor supports offline trigger mode and CANopen bus communication mode. When the device is running, it is not necessary to set the trigger value in real time. Simply configure the trigger value through the debugging software and write the relevant parameters into the sensor to realize the probe. Output level signal when contacting the liquid surface; in complex working conditions, it is necessary to monitor the capacitance value and set it in real time. The trigger value can be monitored and set through the CANopen bus. The CANopen signal transmission rate is up to 1M, which can effectively guarantee the monitoring and setting parameters Real-time; in the case of special models, such as complex multi-needle structure, reagents and probe changes, etc., you can contact our company's technical engineers for data capture and algorithm parameter customization.

The integrated chip solution cannot be adapted to customization.

Detection of blood coagulation bubble stratification:

In equipment such as automatic coagulation analyzers, the plasma and blood cells in the test tube will be differentiated in different levels. When the probe touches the plasma layer and the blood cell layer, different levels of output are required, The equipment performs different actions according to this level signal, The liquid level detection sensor needs to have the function of detecting blood coagulation bubble stratification.

PCS0902 capacitive liquid level detection sensor adopts special software algorithm and hardware scheme, including the function of detecting blood coagulation bubble layering.

Integrated chip solution does not have this function.

Comprehensive cost performance:

The PCS0902 capacitive liquid level detection sensor is a standard mature product. After long-term market verification and repeated upgrades and optimizations, the hardware cost has been extremely low. When the demand is large, it can achieve considerable low cost. The hardware circuit and the software algorithm has been improved, which can greatly save software development costs, reduce development cycles, and reduce system integration complexity.

The price of integrated chip solutions is mainly controlled by integrated chip manufacturers. In addition to related circuits and MCUs, the hardware price is difficult to make low; hardware circuit design and software development require strong R&D capabilities, and new product development requires repeated testing and verification. The long cycle requires a long time investment by software engineers, and the comprehensive investment cost is high.

Long-term supply stability:

The PCS0902 capacitive liquid level detection sensor is a standard mature product and has been widely used in fully automatic medical equipment. The manufacturer is domestic, and the software and hardware solutions rely on imported chips and components. The international trade situation is almost dependent on the price and supply of the product. There is no impact on the cargo cycle, providing a complete set of product solutions, without the need for complicated management of multiple suppliers.

The product price and delivery cycle of integrated chip solutions and are easily affected by the international trade situation. Under the current situation of frequent Sino-US trade wars, it will be extremely unstable in the long term. Adding a liquid level detection sensor requires a variety of electrical components and chips. Multiple suppliers are required to provide ingredients, which increases the difficulty of supplier management.

to sum up:

PCS0902 capacitive liquid level detection sensor, program features: processor plus software algorithm:

• High detection accuracy, support special applications

• Fast response, us level

• Low false alarm rate, strong institutional adaptability

• LAlgorithm supports parameter adjustment and anti-interference

• Low overall cost

• Support bus signal control and IO threshold control

The following is the demonstration video of PCS0902 capacitive liquid level detection sensor liquid level detection: