- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Precision Silent Piston Pumps: A New Era of Fluid Transfer

Precision Silent Piston Pumps: A New Era of Fluid Transfer

In modern industry, efficient, accurate, and reliable fluid transfer systems are key to ensuring smooth production. Piston pumps have been the first choice in many industries due to their excellent performance and wide range of applications. With the continuous advancement of technology, this drive-controlled integrated piston pump can not only provide efficient and stable liquid transfer service, but also greatly simplify the system design and maintenance process.

The test data in this paper are all completed by using the piston pump of the well-known domestic brand Kentuo with the PMC006A3S model of the company's drive controller.

Peculiarity:

1. High precision, low noise, stable torque output

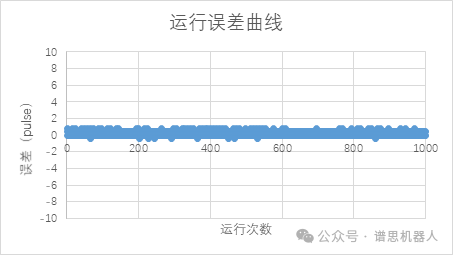

- Built-in PID speed, position, torque control loop. By adjusting the proportional (P), integral (I) and derivative (D) parameters, the system output, reduce the error, and improve the response speed and stability of the system.

- Silent - The noise generated by the friction and movement between mechanical parts of the traditional piston pump is often a problem in the working environment, and the vibration and noise reduction technology is used in the drive control and machinery, the solution achieves the goal of significantly reducing the noise level, which also makes the solution widely used in sensitive areas such as medical equipment and scientific research laboratories.

Accuracy—According to the real-time feedback of the system, the output of the motor is automatically adjusted to ensure that the controller can maintain high-precision control of the motor under various working conditions, which improves the overall stability of the system.

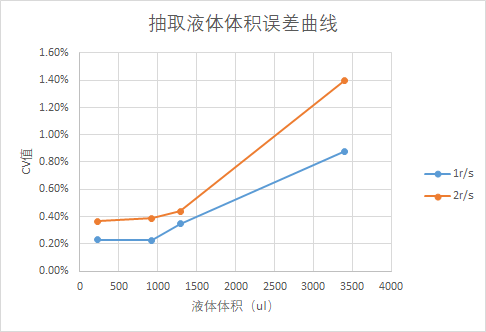

CV value (coefficient of variation): used to count the dispersion of sample data, in industrial control, CV value can be used to monitor the stability of various indicators in the production process. CV = (standard deviation / mean) × 100%. Where standard deviation refers to the degree of dispersion of the data, and mean refers to the mean of the data. The smaller the CV value, the more concentrated the distribution of the data; Conversely, the higher the CV value, the more dispersed the data. This curve is the error of the piston pump pumping different liquid volumes at a speed of 1r/s and 2r/s respectively, and the same speed and the same volume are repeatedly pumped and discharged eleven times. CV = standard deviation of 11 draws/mean volume

The running motor and the small mass ball are placed on the same platform, and the ball is basically free of vibration

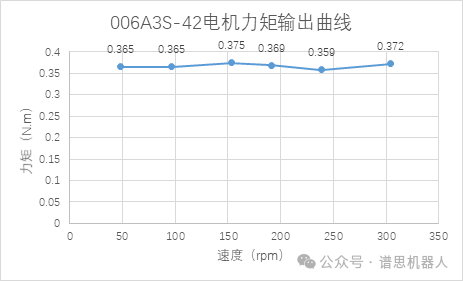

- Torque – Eliminates steady-state errors, reduces system overshoot and oscillation, and maintains constant speed and pressure to output a stable torque, even in the face of changing workload conditions.

- With significant advantages such as high accuracy, low noise and stable torque, the piston pump can achieve accurate pumping and discharge of liquid volume. This not only ensures a stable flow output in complex systems and under various working conditions, but also ensures that both large and small volumes of liquids can be efficiently and accurately pumped and transported.

- Considering the need for frequent replacement testing or upgrade that may exist in the actual use process, the port socket has been comprehensively upgraded, and hot-swap protection measures have been added to each port circuit, which is not only convenient for debugging, but also can effectively prevent about 90% of the electrical damage caused by human error and prolong the service life. The buckle type connector used is stable and reliable, not easy to fall off, and is suitable for various types of application environments. All electrical connections are rigorously tested to ensure long-term reliable operation.

2. Electrical advantages

Apply:

The following all-in-one piston pump is an example of an environmental protection industry. This piston pump is used in COD analyzers, and the controller drives the motor to operate, and the piston pump squeezes the gas inside the piston pump to pump out the liquid to be analyzed. During the entire pumping process, the noise and vibration generated by the operation of the equipment are kept at a very low level, ensuring a quiet and smooth operating environment. The controller also has coil and ext ports reserved for external solenoid valves and optocoupler switches. Solenoid valves are used to control the opening and closing of pipes, while optocoupler switches automatically stop the motor when the piston pump reaches the top.