- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

Advantages and applications of micro-mechanical grippers

Advantages and applications of micro-mechanical grippers

Product Introduction

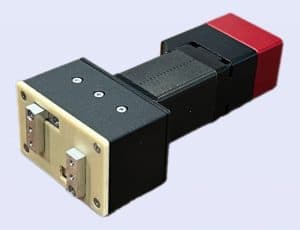

The all-in-one electric gripper based on the Nema 8 stepper motor not only has the high torque and precise control capability brought by the built-in Gearbox, but also has a specially designed replaceable claw head function to adapt to different grasping requirements. In addition, the electric gripper is equipped with a multi-turn encoder to ensure unparalleled position accuracy and reliability in complex application environments. This innovative design makes the device more flexible and changeable in a variety of application scenarios, while supporting the CANopen and Modbus protocols widely used in the industrial communication field to ensure seamless connection with various control systems.

Features and advantages

1. Multi-turn encoder

Absolute position feedback: Multi-turn encoder provides absolute position information, and no recalibration is required even after power failure and restart, ensuring that each startup can immediately enter the working state.

Strong anti-interference ability: Advanced signal processing technology is used to ensure stable data transmission in an electromagnetic interference environment.

2. Replaceable claws:

Flexibility: Users can choose different claws according to specific tasks, such as flat clamp, V-clamp, suction cup, etc., to meet the needs of grasping various objects from round to irregular shapes.

Quick replacement: The convenient quick-change mechanism allows the claw head to be replaced quickly without complex tools, greatly shortening the equipment adjustment time and improving production efficiency.

Customization options: We provide a variety of standard claws to choose from, and also support the customization of special claws according to customer needs to ensure the best fit and work efficiency.

3. Built-in Gearbox:

Increased torque output: With the built-in Gearbox, even a small Nema 8 stepper motor can provide greater torque, suitable for applications that require higher gripping force.

Improve positioning accuracy: The Gearbox can reduce the impact of motor speed fluctuations on the end effector position, thereby achieving more precise position control.

Optimized mechanical structure: The integrated design reduces the number of external connectors, simplifies the installation process, and improves the stability and durability of the system.

4. Multi-protocol support:

Built-in support for CANopen and Modbus communication protocols allows users to choose the most suitable communication method according to actual needs and exchange data with PLC, robot controller or other master station equipment.

5. High-precision control

Combining the advantages of Nema 8 stepper motor, the function of reducer and the precise position feedback provided by multi-turn encoder, it provides excellent position control accuracy, ensuring that each grasping action can achieve millimeter-level accuracy, which is suitable for precision manufacturing and assembly operations.

6. Compact Design:

Taking advantage of the small size of the Nema 8 stepper motor and the integrated design of the built-in gearbox and multi-turn encoder, the overall structure is kept compact, suitable for application scenarios with limited space, without affecting its powerful performance.

7. Easy to integrate:

Standardized interface design and support for multiple communication protocols make it easy to integrate into existing automation systems, whether it is a new equipment or an old line renovation project.

8. Durability and reliability:

Manufactured from high quality materials and undergoing rigorous quality testing, they ensure long-term trouble-free operation, reducing maintenance costs and downtime.

9. Intelligent diagnosis function:

Through CANopen or Modbus protocol, the working status of the gripper can be monitored in real time, including position feedback, fault alarm and other information, helping to improve the reliability and efficiency of the system.

Application Examples

- Automobile manufacturing: Flexible replacement of the claw head according to the shape and size of different parts, combined with the absolute position feedback provided by the multi-turn encoder, enables efficient and precise assembly operations.

- Electronics Manufacturing: For different types of electronic components, select the appropriate gripper and use multi-turn encoders to achieve precise positioning to ensure safe and accurate placement.

- Food packaging: According to the characteristics of different products, such as bottles, boxes or bagged items, the most suitable claws are selected for fast sorting and packaging, while relying on multi-turn encoders to ensure the accuracy of operation.

- Pharmaceutical industry: When handling sensitive items, the gripper can be adjusted to the size and shape of the item and a multi-turn encoder ensures safe and accurate operation.

Conclusion

This all-in-one electric gripper with integrated Nema 8 stepper motor, built-in reducer, multi-turn encoder and replaceable claw head function is an ideal choice for modern intelligent manufacturing. It not only provides excellent technical performance, but also greatly enhances the adaptability and flexibility of the system, and can better cope with diverse and complex grasping tasks.