- Welcome to Pulse Robot

- +86-23-63207381

- +8613677602178

- sales@pusirobot.com

NEMA11 lntegrated closed-loop stepper motor

Holding torque

NEMA 11

L=30mm 0.06N.m

L=40mm 0.08N.m

L=50mm 0.12N.m

Main characteristics

Technical data

General

|

Nema11 closed-loop stepper motor series

|

|

| Host |

PC,PLC,MCU

|

| Support motor |

2-phase 4-wire 1.8°/0.9° stepper motor

|

| The development environment |

VC C# Labviwe VB Linux Python

|

| The power supply voltage |

DC 9-36V

|

| Motor Current |

DC 0.7A L=30mm |

| Microstepping |

0/2/4/8/16/32/64/128 adjustable

|

| Temperature |

-40℃~80℃

|

| Incremental resolution |

Suppport external 200-8000PPR(Default 4000)

|

| Absolute resolution |

12 bit single-turn/multi-turn absolute encoder

|

| Holding torque |

0.06N.m L=30mm

0.08N.m L=40mm 0.12N.m L=50mm |

| Durability |

Over 20,000 hours

|

The input

| General I/O |

Description

|

| IO function |

External stop input, brake control, digital input/output, analog input, factory reset, 5V output

|

| The input specifications |

Digital input voltage: 0-5V

Analog speed regulation input voltage: 0-3.3V External stop input voltage: 0-5V |

Control mode

|

|

Description

|

| Control mode |

Support Position/Velocity/PP/PV/SP/Analog Position/Analog velocity mode etc. motion mode

|

| Mode switching |

Specified instruction switching

|

Communication

|

Description

|

|

| Protocol |

CANopen DS301/Modbus-RTU

|

| Baud rate |

5k-1M bps continuously adjustable / 9.6K-115.2K bps adjustable

|

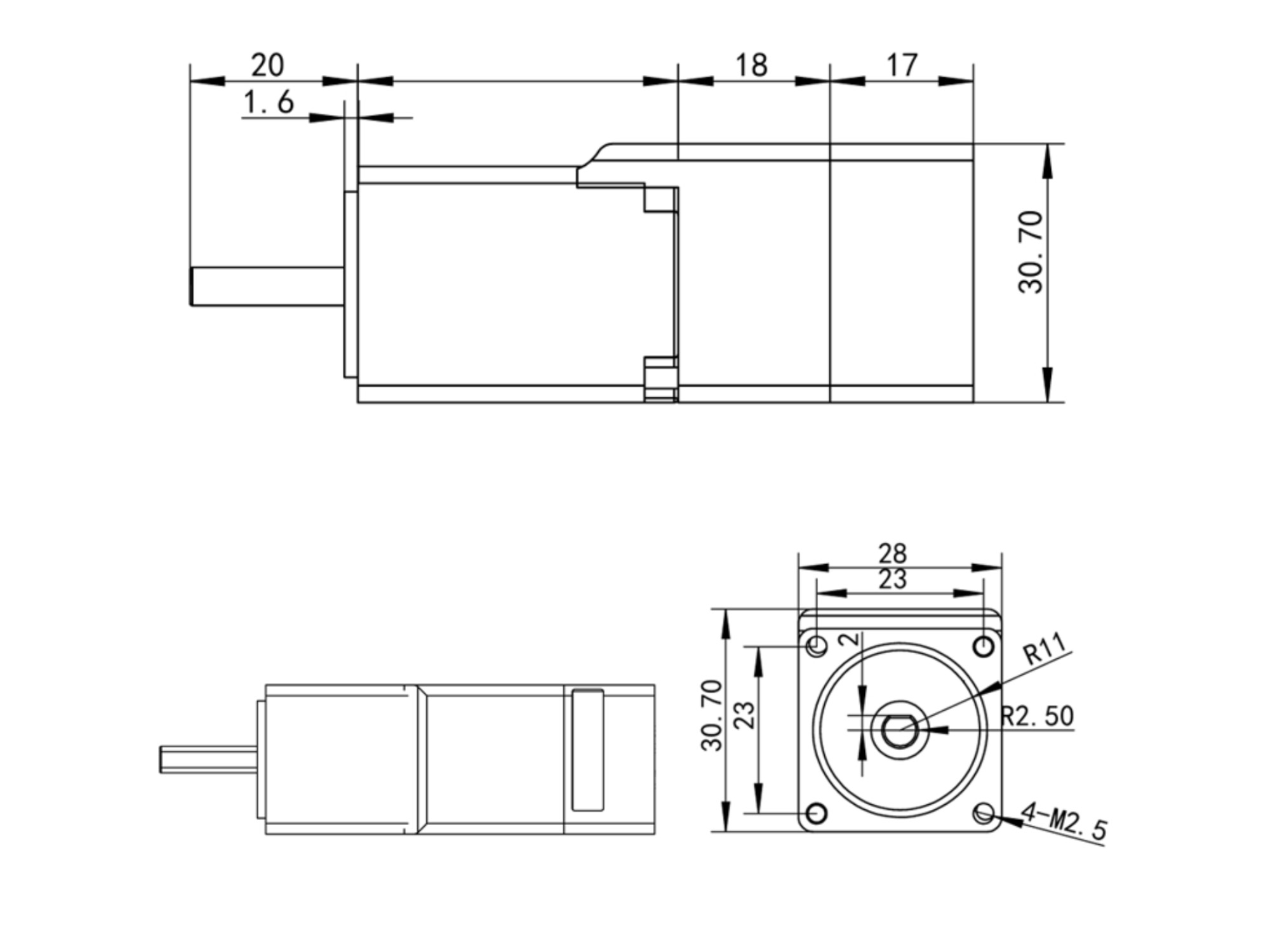

Size

Download

| CAD |

.DWG

|

| 3D file |

.STP(Contact customer service)

|

| The user manual | |

| Debug software | Development documentation | Certification |

Functional features

| Function |

Description

|

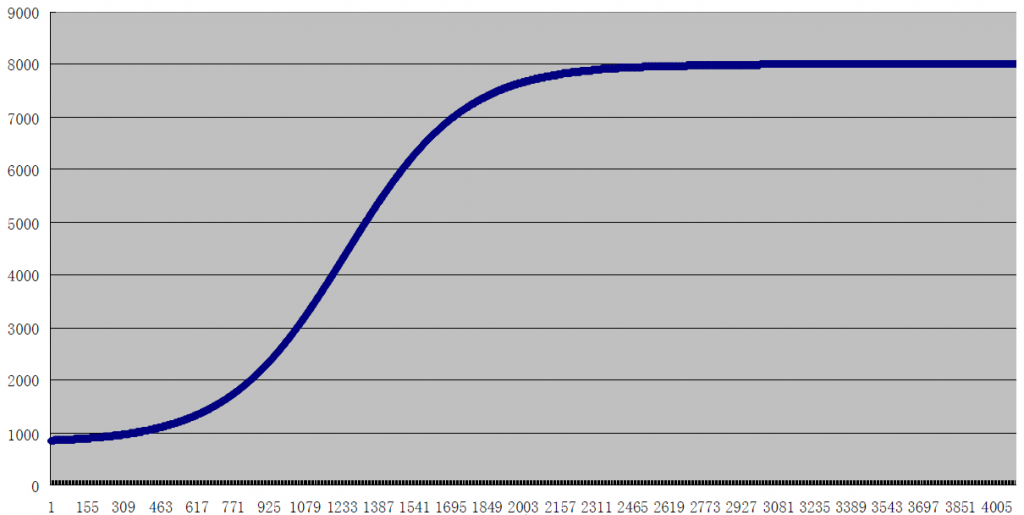

| S-curve acceleration and deceleration automatic control |

Support separate configuration of starting speed, stopping speed, acceleration and deceleration. Acceleration and deceleration support 8-gear control. Acceleration and deceleration simulation diagram is as follows

|

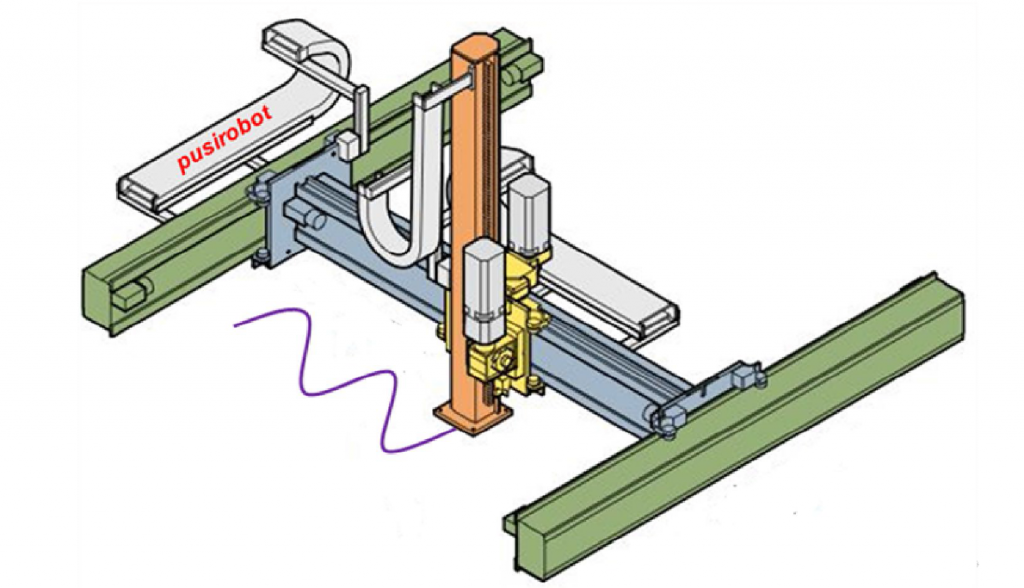

| PVT multi-axis interpolation |

It supports precise control of the position and speed of multiple axes on the same time coordinate, so that the end mechanism can realize straight line, arc and complex curve motion trajectory, as shown in the figure below

|

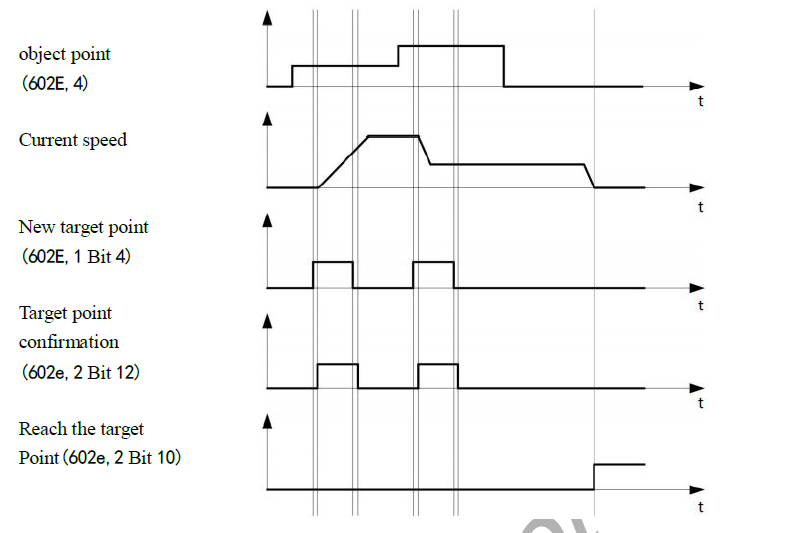

| PP model |

In the process of PP mode operation, a set of new parameters can be written by the host computer. It can be selected to smooth the transition from the previous operation parameters to the new parameters, or to run with the new parameters after the operation of the old parameters, as shown in the figure below

|