2025-01-06

2024-12-25

2023-11-03

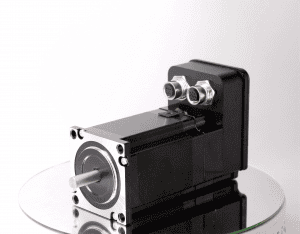

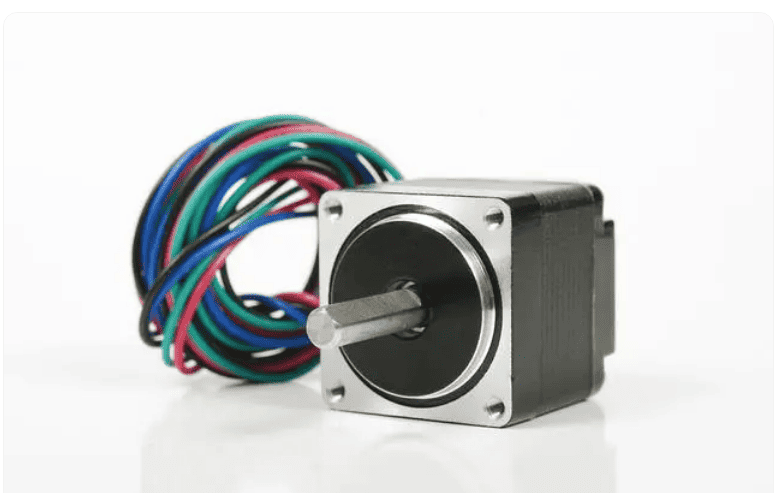

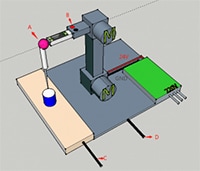

When selecting the stepping motor, first ensure that the output power of the stepping motor is greater than the power required by the load. When selecting the power stepping motor, the load torque of the mechanical system must be calculated first.